Laminar Air Flow

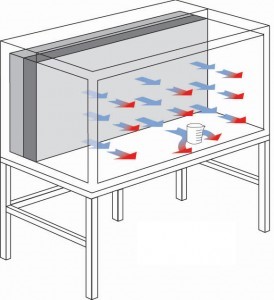

Horizontal Laminar Air Flow

Room air (in red) enters the system from behind the HEPA filter; 99.99% particle-free air is forced in a back-to-front direction across the work surface.

Although both airflow designs provide effective sweeping action near the filter face, their respective flow patterns eventually encounter disruptions that often tip the scale in favour of one or the other configuration. In a vertical-flow hood, the obvious obstacle is the work surface. A perforated or rod-top work surface allows the laminar air stream to pass through the hood with minimal obstruction, but these tops can be a problem in operations involving liquids or small parts. If you’re working with these materials and want to avoid picking up parts off the floor, a horizontal flow design may be preferable.

Yet even a solid top may not rule out vertical flow if work is performed above the work surface. If sterile or particle-sensitive processes are performed in a clean, sterile zone midway between the work surface and the filter face, a vertical flow hood is generally acceptable. One such operation is sterile compounding, in which injectables or sterile packages are prepared above, not on, the work surface. As long as hands and other contamination sources move up and down, not sideways above a sample, sensitive materials will remain clean.

Finally, consider the effects on operators of air exiting the laminar flow hood. Although horizontal laminar flow, with air traveling from the rear of the hood and exiting the front opening, may not encounter large obstructions inside the hood, it does eventually encounter the person performing the work. Any annoying substances, such as soldering fumes or fine powders, may be blown into the operator’s face. While this collision may not compromise the laminar flow where work is performed, it may pose a health risk. In such cases, vertical flow is probably preferable.

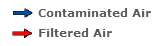

Vertical Laminar Air Flow

Room air (in red) enters the system from above the HEPA filter; 99.99% particle-free air is forced downward toward the work surface.

A clean bench using a vertical laminar flow design is also preferable where floor space is at a premium. Because this configuration stacks the fan/filter module on top of the hood, a vertical laminar flow hood can generally be installed on a standard lab bench. By contrast, a horizontal-flow hood requires additional depth to accommodate the rear-mount filter/fan unit with some additional rear clearance to allow air to enter the system. These clearance requirements necessitate a deeper bench and more floor space than a vertical flow system.

Biosafety Cabinet

Biosafety Cabinet Class I

Class I BIOSAFETY is designed for operator and environment protection from hazardous materials and substances for operator's health. The operation is based on the forced removal of hazardous substances from the working zone through the air up-flow, with high-effective air filtration and exhausting the air into the environment. Due to the unidirectional laminar air flow, there is no risk of their cross-contamination when there are more than 2 agents working on the equipment.

Biosafety Cabinet Class II - A1 & A2

Class II Biosafety Cabinet Type A1 & A2 are designed for the security and protection of operator’s product and environment from pathogenic agents and microorganisms transmitted in respiratory way and also for creation of a bacterial dust free air environment. It has a common plenum from which 30% of air is exhausted, and 70% re-circulated to the work area as part of the downflow. Type A cabinets drain out air directly back to the laboratory, and they may contain positive pressure contaminated plenums. When toxic chemicals must be employed as an adjunct to microbiological processes, these cabinets should not be used. Exhaust HEPA filtration only.

Removes airborne aerosols including biohazards, and not chemical fumes.

The Class II Type A1 consists of the positively-pressurized contaminated plenum bordering the ambient environment, and therefore is less safer than the Class II Type A2 that has a negative pressure surrounding the positively pressurized contaminated plenum. In any unlikely event of a leakage on the positive plenum, the leaking aerosol will be pulled by the negative pressure back to the positive plenum, which prevents it from leaking out. On the grounds of safety, the Type A1 design is now considered obsolete. In the A2 cabinet, approximately 70% of air from the positive plenum is re-circulated as down flow

Biosafety Cabinet Class II - B1

The Class II Type B1 biological safety cabinet has a common plenum from which 70% of air is exhausted, and 30% re-circulated to the work area as the down flow.

Type B1 cabinets also have a dedicated exhaust feature that eliminates re-circulation when work is performed towards the back within the interior of the cabinet. Toxic chemicals employed as an adjunct to microbiological processes should only be employed if they do not interfere with work when re-circulated in the downflow.

Biosafety Cabinet Class II - B2

In the case of Class II Type B2 cabinet all inflow and downflow air is exhausted after HEPA filtration to the external environment without recirculation within the cabinet. This means that Type B2 cabinets are apt for working with toxic chemicals employed as an adjunct to microbiological processes under all conditions since no re-circulation occurs. In theory, Type B2 cabinets may be measured to be the safest of all Class II biological safety cabinets since the total exhaust feature acts as a fail-safe in the event that the downflow and / or exhaust HEPA filtration systems cease to function normally. However, Class II Type B2 cabinets, in practice, are difficult to install, balance and maintain.

Biosafety Cabinet Class III

The Class III biological safety cabinet provides an absolute level of safety, which cannot be attained with Class I and Class II cabinets. All Class III cabinets are usually of welded metal construction and are designed to be gas tight. Work is performed through glove ports in the front of the cabinet. During routine operation, negative pressure relative to the ambient environment is maintained within the cabinet. This provides an additional fail-safe mechanism in case physical containment is compromised. On all Class III cabinets, a supply of HEPA filtered air provides product protection and prevents cross contamination of samples. Generally the exhaust air is HEPA filtered and incinerated. Alternatively, double HEPA filtration with two filters in series may be utilized.

Materials are transferred into the cabinet using a pass-through unit installed at the side of the work area. Class III cabinets usually exhaust air back to the laboratory; however, air may also be exhausted via a dedicated ductwork system to the external environment. When a dedicated ductwork system is employed, they are also suitable for work employing toxic chemicals as an adjunct to microbiological processes. All Class III biological safety cabinets are suitable for work with microbiological agents assigned to biosafety levels 1, 2, 3 and 4. They are frequently specified for work involving the most lethal biological hazards.

Reverse Laminar Air Flow

Dispensing/Sampling Booth

Dispensing/Sampling Booth provides a safe, HEPA Filtered environment, for the dispensing of hazardous drug powders. Air is pulled away from user thru rear-wall pre-filters, trapping powders; recirculating air through ceiling mounted high efficiency particulate air (HEPA) filter rated 99.99% efficient at 0.3 microns.) protects the operators from toxic chemicals / raw materials used for manufacturing of tablets, medicines, capsules etc from external contamination during the process of weighing or measuring. It is ideal where a high degree of flexibility is desired. Containment is achieved by air movement. The product also known as Pharmaceutical Sampling Booth and Pharmaceutical Dispensing Booth.

Dispensing/Sampling Booth has been designed to provide a Class 100 working environment at rest, with built-in scavenging system to ensure protection for the product, operator and surrounding environment.

The system comprises:

- Imported Mini pleat HEPA Filter with hot melt technology, which conforms to EU 13 Grade, with an efficiency rating better than 99.99% for 0.3μ at supply position

- Imported Mini pleat HEPA Filter with hot melt technology, which conforms to EU 13 Grade, with an efficiency rating better than 99.99% for 0.3μ at exhaust position

- Pre filter which conforms to EU 4 Grade, with efficiency of 90% down to 10µ. These Filters are basically made from micro-fibre-glass media and are inherently washable

- Intermediate filter which conforms to EU 7 Grade, with efficiency of 95% down to 3µ. These Filters are basically made from micro-fibre-glass media and are inherently washable

- Motor Blower provided are statically and dynamically balanced, Supply of sufficient capacity and static pressure is used to take care of airflow requirement for entire life of HEPA. The blower is high-performance, noise abated, light weighted statically and dynamically balanced

- SS 304 Double Walled Side Panels

- Mechanical Differential Pressure Gauge (0mm-25mm: 2 Nos.) to monitor pressure drop across intermediate filter

- Differential Pressure Gauge HEPA filter and (0mm-10mm: 1 No.) To monitor pressure drop across PRE Filter with respect to ambient

- Electrical control panel mounted on the side panel of the unit

- Tube Light

- ON/OFF Switches for motor

- 5/15 Amp single-phase switch socket for external equipment

- PAO Test port at upstream of HEPA filter

Pass Box

Static Pass Box

Pass Box aids in the material transfer without much personnel movement. Furthermore, the Static Pass Box also acts as a hindrance for entrance of contaminants in clean room and other classified areas. pass box static is designed to minimize traffic and contamination entry into the clean room.

Static Pass Box is an inexpensive way to maintain the cleanliness of your clean room. These boxes operate on the principle of one door opening at a time with electromagnetic interlocking so as to avoid any possibility of cross contamination. With stainless steel coating and rigid base these tailor made equipment provide optimum performance. They are available in Stainless Steel Construction with interlocking arrangement.

Dynamic Pass Box

Dynamic Pass Box are self-contained units installed at the entrance to clean rooms. They minimize the amount of particulate contamination and is easy to install and adaptable to existing facilities. These boxes operate on the principle of one door opening at a time with electromagnetic interlocking so as to avoid any possibility of cross contamination. Our Clean Room Pass Box comes under the international standard and is used for transferring the material form one clean room to other clean room.

Dynamic Pass Box assists in transfer of materials driven through a controlled environment but without much personnel movement. Furthermore, this box helps in prevention of contaminants entrance either in the clean room or between various classified areas. The pass box also known as Clean Room Pass Box.

Fume Exhaust Hood

Fume Hoods are equipments that are used to ensure safety for the user as they won’t be exposed to too many hazardous and dangerous fumes. Fume Hood capture the fumes/effluents released during any given experiment, contain them in the enclosure and then emit through their well-designed exhaust system.

We specialize in standard Fume Hood and customized Chemical Fume Hood. Fume hoods typically protect only the user, and are most commonly used in laboratories where hazardous or noxious chemicals are released during testing, research, development or teaching. They are also used in industrial applications or other activities where hazardous or noxious vapors, gases or dusts are generated or released.

Air Shower

Clean rooms provide controlled environments for the production of contaminant-free products. Air showers play a vital role in maintaining these clean-critical settings by removing loose particles of contamination from people and products before they enter the clean room.

Self-cleaning air showers help reduce product defects and increase production yields. These devices can also improve the performance of and reduce maintenance needs for the clean room itself by lowering the overall contamination load. Without an air shower’s “pre-cleaning” process, a cleanroom’s air filtration system would have to absorb all contaminants, which would increase energy consumption and maintenance costs.

Our Products designs and manufactures cleanroom air showers in a range of standard air shower sizes and configurations. We have self-cleaning air showers to meet most customer requirements; however, if your cleanroom requires a special or unique entry system, we also provide custom air showers that are built to match your unique specifications.

Presssure Module

Positive Pressure Module

We are one of the few companies engaged in offering a wide range of Positive Pressure Modules for our clients to choose from. The system feeds fresh air into the room after the air is passed through HEPA filtration. Then later the modules recalculate the air back into the room through the filter itself. Moreover, the AC connectable module that filters the cooled air, sterilizes it and pass it into the room.

Air Curtain

Air Curtains are made up of centrifugal forward curved blade. They are available in decorative, satin aluminum anodized finish as well as in stainless steel. Their cost-effectiveness makes them a preferred choice amongst others in competition

We deal in a various types of air curtains using mild steel, galvanized sheets, stainless steel, board laminates, etc. However specific sizes can also be provided by us as per the customer's applications. These air curtains provide thermal barrier to prevent heat transfer to and from premises. These also prevent dust or insect infiltration into usable space.

Features :

- Switch control

- Fireproof metal body

- Super slim design saves space

- Available in decorative, satin aluminum anodized and stainless steel finish

Strip Air Curtain

The strip air curtain that we offer has almost limitless applications. This is extensively beneficial in very large openings or single doorways. Our strip air curtains are commonly used where it is necessary to stop insects from entering a building to meet with FDA or NSF requirements. Bugs approaching the door way will be stopped by a screen of air that is too powerful to penetrate.

Key Features:

- PVC strip curtain maintains Humidity, Temperature and Hygiene during traffic movement through the doors.

- Reduces Heat or cold air loss by opening only wide enough to let a person or vehicle to pass through an then closing automatically.

- Restricts movements of Air pollutants such as dirt, dust and smoke.

- Restricts movements of Air pollutants such as dirt, dust and smoke.

- Transparency provides excellent visibility for through traffic.

- Increase employees comfort by keeping temperature and humidity under control.

- Isolates noisy machinery and equipment, work station and loading docks from other work areas.

- Provides bird and flying insect control outside or between work areas.

- Strong and durable, top quality PVC material features. Heavy duty strength and tear resistance for long life.

Softwall Cleanroom

Clean Air Products’ standard softwall cleanrooms provide a number of benefits and advantages that make them an effective solution for any clean-critical application.

- High functionality

- Low cost

- Durable yet lightweight

- Modular designs for easy assembly and disassembly

- Easy to reconfigure or expand

- Portable and easy to relocate

- Two mounting options (freestanding or ceiling-hung)

- Ideal for smaller spaces

To meet your clean-critical requirements, we can provide softwall clean rooms in any classification between Class 100 (ISO 5) and Class 100,000 (ISO 8).

- 99.99% test on 0.3 micron HEPA filters

- Aluminum frame HEPA filters

- LED lights

- Clear curtains

- Filters and lights

- High-strength tubular steel frame with white baked-enamel finish

Our modular softwall clean rooms utilize motorized, ceiling-mounted HEPA filters and specialized LED cleanroom lights. Cleanrooms are fully enclosed by heavy-gauge, clear, polished-vinyl curtains. Curtains are installed in sections, with the tops sealed against the support frames and vertical seams overlapped to prevent contamination from infiltrating the clean room environment. Simply spread two curtain sections apart to enter or exit the cleanroom—curtains automatically re-seal as the two edges come back together.

Garment Storage Cabinet

Garment Storage Cabinet is one of essential equipment in any clean room. It is used to keep cleanroom garments, tools, wipes and other materials and plays important role in maintaining cleanliness of a cleanroom environment.

Cleanroom Accessories

Filters

HEPA Filter

HEPA is an acronym for "High Efficiency Particulate Air" or "High Efficiency Particulate Arrestance." This acronym refers to a filter that is manufactured, tested, certified, and labeled in accordance with current HEPA filter standards. There are several sub-classes within the HEPA classification. The minimum HEPA category requires the filter to capture 99.97% of the 0.3-micron (0.000012-inch) particles in the air passing through the filter

HEPA is an acronym that stands for High Efficiency Particulate Air, so a HEPA filter is a High Efficiency Particulate Air filter. Filters, whether for an air purifier or other implementation, come with many benefits and claims.

What sets HEPA filters apart from the rest is their claims are more than just claims. Because in order to be called a true HEPA filter it has to be first be tested and approved, you know exactly what to expect. The Institute of Environmental Sciences and Technology dictates that a HEPA filter must trap 99.97% of particulates 0.3 microns or larger. This does not mean that the filter cannot trap particles smaller than 0.3 microns, because many HEPA filters can; it is simply the threshold that must be reached in order to carry the HEPA name.

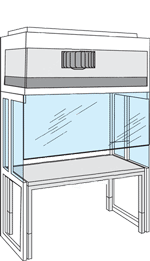

Cleanroom Fan Filter Units

Cleanroom fan filter units are self-contained devices that utilize HEPA filters. We offer a full line of standard and custom fan filter units, with numerous options available to meet your specific cleanroom requirements.

Motor Blower

A blower motor is the component within a home’s HVAC system. At the heart of most automotive HVAC systems is a component called a blower motor. This descriptive term refers to the fact that these components are electric motors that are attached to fans and used to move air through the HVAC system. In most cases, a single blower motor is responsible for delivering both hot and cool air, on demand, depending on how the climate controls are set.

UV Lamps

The UV light uses a short wavelength that can destroy harmful microorganisms within the hood. This process removes the microorganism’s reproductive capabilities and kills the germs within the hood.

Door

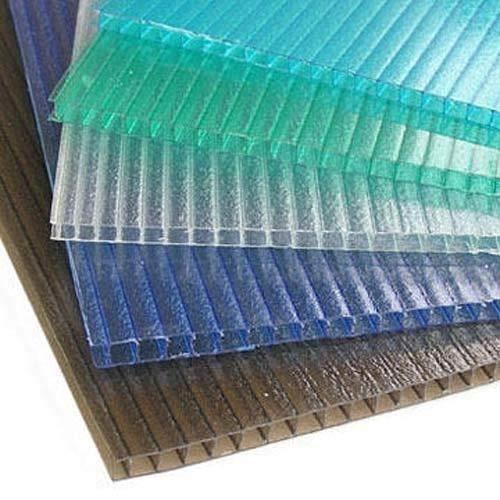

Polycarbonate Sheet

Polycarbonate is a thermoplastic that comes in a transparent sheet. It is incredibly tough and absorbs minimal moisture, making it resistant to impact damage as well as water damage. It's also flame-retardant and chemical resistant.

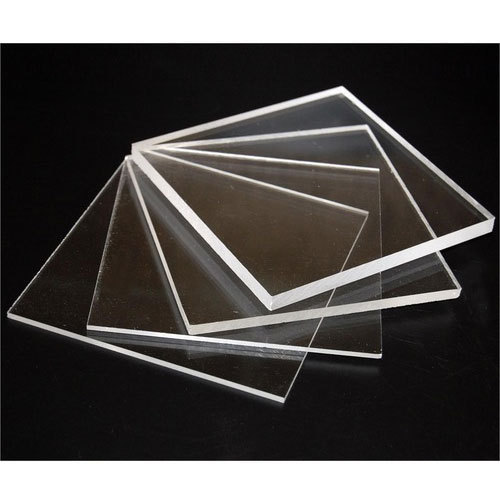

Acrylic Sheet

Acrylic is a transparent plastic material with outstanding strength, stiffness, and optical clarity. Acrylic sheet is easy to fabricate, bonds well with adhesives and solvents, and is easy to thermoform. It has superior weathering properties compared to many other transparent plastics. Acrylic sheet exhibits glass-like qualities—clarity, brilliance, and transparency—but at half the weight and many times the impact resistance of glass. From durable signs and skylights, to eye-catching retail store fixtures, displays and shelves, acrylic plastics provide outstanding versatility, durability, and aesthetic qualities.

Mobile Trolley

Mobile Trolley is designed for transporting sterile products under ISO Class 5 (Class 100) particle free work area for storing sterile products to meet storage needs while making a positive contribution to maintaining the cleanliness of your controlled cleanroom environment.

Chemical Bench

Chemical benches are designed for processes involving corrosive chemicals. Each bench is designed for handling specific types of chemicals and can generally be classified as Acid benches or Solvent benches.

Acid benches are manufactured from polypropylene with polypropylene worktops and fittings. Solvent benches can be manufactured completely from stainless steel or using a polypropylene carcass with stainless steel liners incorporating stainless steel worktops and fittings.

The benches are custom designed for the particular process and are fitted out as necessary to include: DI water taps & guns, nitrogen taps and guns, wash/weir tanks, dump rinsers, aspirators for the extraction and dilution of acids, Quartz tanks, hot plates, ultrasonic tanks, sinks, hinged and sliding visors, folding night covers, chemical baths, etc.

Consumables

Lab Coats

Lint-Free Lab Coats

- Lint-free lab coats are extremely breathable and comfortable. Elastic wrists and no-pocket style make this lab coat great for less strict cleanrooms.

Antistatic Coverall

- Materials: Terylene fiber 99 and conductive fiber 1%

- Distance of conductive fiber: 5mm strip, 5mm grid, 2.7mm grid.

- Sizes : Medium, Large, XL, XXL, XXXL

- Colors: white, blue

Lab Coat Jacket

- As these coat are made up of Polyester , so these are 100 % Safe for ESD works & also Resistive to Static Charge.

Cleanroom Shoes

Autoclavable long boots with cuffs

- Material Name: Heat-resistant rubber

- Material: Heat-resistant rubber x III

- Color: White

- Size: 23.0-28.0 1cm pitch

Autoclavable boots with zippers

- Color: White

- Size: 22.0-30.0 1cm pitch

Long boots and Anti electrostatic work shoes

- Material: Urethane sole

- Color: White, Pink, Blue

- Size: 22.0-28.0 0.5cm pitch & 28.0-31.0 1cm pitch

Long boots with zippers and Anti electrostatic work shoes

- Material: Urethane sole

- Color: White, Pink, Blue

- Size: 22.0-28.0 0.5cm pitch & 28.0-31.0 1cm pitch

Autoclavable long boots with iron cores in the toe areas

- Material Name: Heat-resistant rubber

- Material: Heat-resistant rubber + iron cores in the toe areas

- Color: White

- Size: 23.0-28.0 1cm pitch

Half length Toffeln wellington boot

- A unisex and washable wellington

- Lightweight PVC with non marking soles

- Offering the best protection from fluids

Fabric Antistatic Shoes

- Insole Material: Non Woven Fabric

- Material: Fabric

- Sole Color: White

- Available Size: Customize

Shoe Covers

Non Slip Over Shoe

- Length: 16"

- Blue dimpled PVC sole, which prevents slipping

- The upper is manufactured out of polypropylene, making it light and comfortable Excellent value

- Perfect for someone who wears overshoes for a considerable amount of time

- Pack Size: 100 pairs

Polyethylene 16" Over Shoes Economy

- Elasticated top

- Size: 16" - will typically cover work shoes

Face Mask

- Layer Face Mask with Knitted Earloops features a medium filter of meltblown polypropylene.

- Berkshire masks protect cleanrooms and controlled environments from human contamination.

- Layer Face Mask with Polyurethane Headbands features a medium filter made of polypropylene.

- Easy breathing comfort with excellent performance.

Disposable Beard Covers

- Disposable beard covers are economical and effective choice for sanitary protection. These beard protectors are made from breathable spunbond polypropylene material without latex. A one size fits all. Easy to slip on. Stays in position using an elastic band.

Hair Caps

Disposable Bouffant Caps

Spun-Bounded Polypropylene, Hair Head Cover Net, Non-Woven, Medical, Labs, Nurse, Tattoo, Food Service, Health, Hospital

- Universal Fit

- Low Lint

- Hypoallergenic

- Elastic Band

Blue Non Woven Bouffant Cap

- Color: Blue

- Material: Non Woven

- Packaging Type: Packet

- Pattern: Plain

- Usage: Hospitals, Labs

Gloves

Cleanroom Gloves

- 100% polyester knitted seamless half-finger gloves, made by 15 gauge knitting machine. Free size. Inner gloves are knitted with continuous filament fibre, they are int free and are designed to be used with barrier gloves to give greater comfort to the operator . The inner gloves are available in a full or half finger version and are suitable for operators with allergies

Co-Polymer

- Specially developed to answer the major concerns of clean room operators are made of a new blend of PVC resins, which combines high cleanliness (extremely low particle emissions and low metal ion content) with exceptional physical properties. High sensitivity, enhanced tensile strength and elongation giving greater operator comfort. Superior Cleanliness: class 10, class 100. Exceptionally low metal ion content. Antistatic: Surface leakage resistance of 2.1X 10 to the power of 11 ohm. Ideal for employees with known allergies to latex proteins. Length 12", ambidextrous. Double bagged in controlled clean room environment.

PVC Glove

- PVC glove, white, with opaque sleeve suitable for various chemical applications. Offering good grip and sensitivity. Available with Textured or Micro finish palm. Glove length 28 cm, overall length 60 cm. EN 388:1994, EN374-3:1994.

Light Weight

- 100% cotton interlock gloves, with 3 seams on back, bleached white.

Nylon Glove

- White nylon gloves

Nitrile "Partner" Gloves

- Nitrile ambidextrous gloves

- powder-free

- protein free ,blue

- 100 pcs/pack, 10 packs/carton

- size: S, M, L, XL

Wipes

Pharmacy Wipes-Non Sterile in 100's

- Sterile Pharmacy Wipes made from a highly absorbent hydroentangled binder free 68gsm polyester / cellulose nonwoven fabric.

- Extremely low particle shedding.

- Extremely low extractables.Excellent chemical resistance. 300 x 300mm (12 x 12 inches)

- Flatpacked-non folded. 100 wipes per pack - 25 packs per case = 2500 wipes per case

Characteristics:

- Solvent resistant. Very high absorbency. Low lint. Silicone free. Excellent wet & dry strength. Low extractables. Heavy sealed double polybags. Gamma sterilized

- This highly abrasion-resistant wiping cloth can be used repeatedly. It's antistatic, easy to use and economical.

Tacky Mats

- A stack of polyethylene filmsheets, with a specially treated pressure sensitive adhesive on one side. When walked or rolled over, these mats will remove any last trace of contamination on shoe heels, soles and trolley wheels. When loaded with contaminates, it is peeled off exposing a new clean sheet for use, thus eliminating cleaning and washing. The mat is slip-proof, non-contaminating and will not be damaged by footwear or wheels.