About Us

We, AIR CALIBRE SYSTEMS (ACS) are a recently established specialized company dealing in Clean Air Technology ( C.A.T ) and also trade in a wide array of clean room equipment, accessories and consumables. We deal with products of the highest grade and quality which are designed to maximize the level of cleanliness and also to minimize particulate contamination.

We, (ACS) in this short span of time have established partnerships with all the leading suppliers in the Global/Indian market who supply quality products in the niche space of C.A.T.

We currently have three well experienced and professionally qualified and trained colleagues who have over 15 years of experience in the same industry. We would like to inform you that one of our objective is to be a part of the Green Movement which would result in us jointly controlling the contamination in the Environment surrounding us.

We have started of this new venture with the hope of seeking your invaluable support, assistance and blessings in making this organization create a niche in the area of C.A.T.

We (ACS) deal in all equipments pertaining to C.A.T including but not limited to various cleanroom equipment for example, Particle count, Photometer, Lamainar Air Flow Workstations ( Horizontal/Vertical ), Biosafety Cabinets, Airshowers, Pass-Thrus ( Pass Box ), Fume Hoods, HEPA Filters, Air curtains & Softwall Cleanrooms and also in Clean room consumables like Cleanroom garments, Booties ,Gloves, sticky mats etc.

Our Vision

We (ACS) have complete customer satisfaction ( sales and post sales ) as our primary goal. We have our goal of being among the top 3 C.A.T companies in......

Our Commitment

We (ACS) strive hard to find the best possible solution for our valued customers and work continuously towards the goal of achieving the best in terms of quality, price & timely delivery and service.

We (ACS) commit to provide our customers the highest of quality products in C.A.T.

Regulotary Compliance

We (ACS) promise that all products we deal with conform to the various quality parameters throughout its operating life. Also we confirm that all the products we deal in comply with statutory and regulatory requirements pertaining to our industry.

Validations

- All

- Test

- Service

Air Velocity Profile

Test

Filter Integrity

Test

Particle Count

Test

Recovery

Test

Air Flow Pattern

Test

Noise Level

Test

Light Intensity

Test

Air Purity

Test

Service

Service

Services

Cleanroom and cleanroom equipments are capital intensive and requiring regular testing to maximize the control of contamination in the environment. Productivity maximization can only be achieved by regular comprehensive maintenance and testing. This will also reduce downtime and product defects resulting in increased productivity.

Our methodology of testing meets federal standard and ISO Standard

Equipment We Service & Calibrate

- Laminar Air Flow work stations

- Biosafety Cabinets

- Air showers & Air curtain

- Positive Pressure Modules

- HEPA & ULPA filters

- Pass Box

- Fume Exhaust Hood

- Sampling & Dispensing Booth

- Wet chemical benches

- Isolators

- AHU units.... etc...

Tests we carry out for Clean room area and Equipment

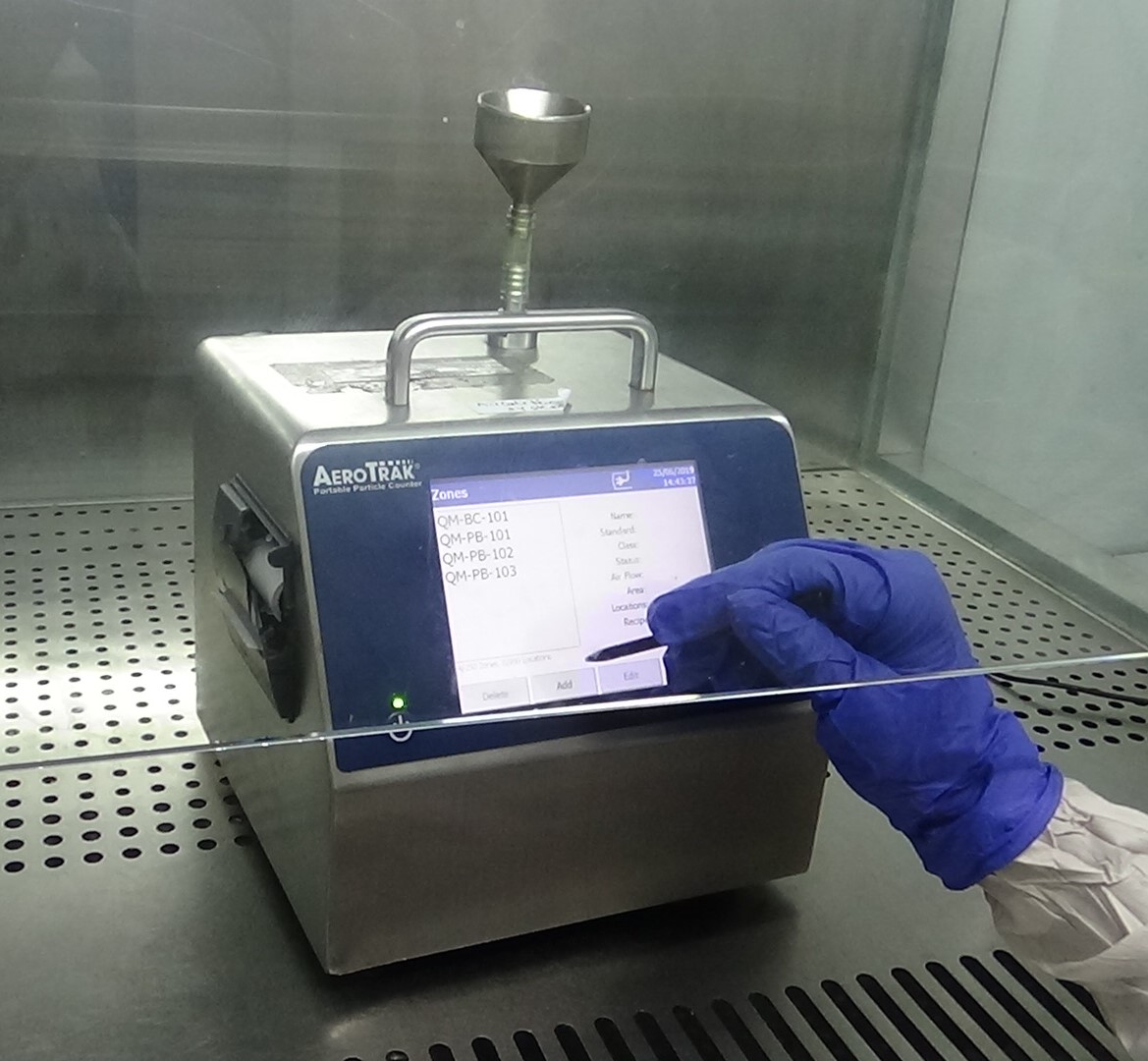

- Particle count testing ( Federal Standard 209E and ISO 14644)

- HEPA Filter leak testing (using PAO or DOP Oil)

- Airflow Parallelism and Air Pattern Studies

- Air Velocity Profile includes air changes per hour and air balancing

- Temperature & Humidity

- Differential Pressurisation Test

- Recovery test for Uni-directional Clean rooms

- Noise Level tests

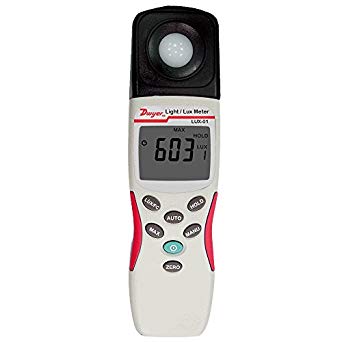

- Light Intensity tests

List of Equipment we use to meet tests

- Aerosol Photo Meter Make ATI Model No: 2H Serial Number-20135

- Aerosol Generator 4B Make ATI

- Particle Counter Make Lasair III Model No: 310C Serial No: 62497

- Anemometer Dwyer make Model

- Anemometer Lutron Make Model No. AM 4204

- Light Meter

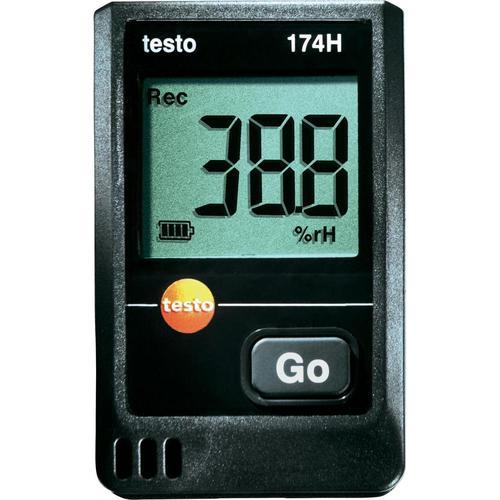

- Hygro Meter

FAQs

1. What is a Biological Safety Cabinet?

A biological safety cabinet (BSC) is a ventilated cabinet which uses a combination of HEPA filtration, laminar air flow and containment to provide personnel, product or environmental protection from biohazardous agents. This is accomplished by air intake and recirculation that is filtered prior to exhausting to the cabinet exterior. It is distinguished from a chemical fume hood by the presence of HEPA filtration and the laminar nature of the air flow.

2. What is a Laminar Flow Cabinet?

A laminar flow cabinet or laminar flow hood or tissue culture hood is a carefully enclosed bench designed to prevent contamination of semiconductor wafers, biological samples, or any particle sensitive device. Air is drawn through a High Efficiency Particulate Air (HEPA) filter and blown in a very smooth, laminar flow towards the user or towards the work surface. The cabinet is usually made of stainless steel with no gaps or joints where spores might collect. Laminar flow cabinets do not protect the user or the environment and cannot be used with infectious material.

3. What is a HEPA filter?

HEPA stands for High Efficiency Particulate Air filter and is capable of removing microscopic organisms with an efficiency of at least 99.97%. These filters help protect the user, the product in the workspace and the environment, but must be checked annually to ensure that they are functioning properly.

4. What is a Cleanroom?

A Cleanroom is defined by ISO14644-1 as "a room in which the concentration of airborne particles is controlled, and which is constructed and used in a manner to minimize the introduction, generation, and retention of particles inside the room and in which other relevant parameters, e.g. temperature, humidity, and pressure, are controlled as necessary." The design of cleanroom HVAC systems is a specialty area requiring the unique understanding of cleanliness guidelines, airflow, room pressurization, code requirements, specialty equipment, precise control, and many more details.

5. Describe Cleanroom Do’s.

- Only authorized personnel will be allowed inside the cleanroom.

- Only take what is necessary into the cleanroom.

- Only dedicated tools are allowed in the cleanroom.

- Gown in the prescribed manner over your non-frayed/non-ripped, low-linting clothes.

- Always make sure that all the head/facial hair is covered inside the cleanroom.

- When using an air shower, turn a minimum of three times around (slowly) during the ON cycle time.

- Keep doors from clean room to gowning area closed.

- Keep the cleanroom garments closed at all times while in the cleanroom.

- Use pass-through properly.

- Maintain good air flow management. "Product gets air first."

- Be discrete in coughing, sneezing, blowing your nose. If you can, go into the service area or gowning room. At the very least, turn away from the processing area and change your vinyl gloves before commencing processing again.

6. Describe Cleanroom Don’t’s.

- People who have not been trained properly to meet the cleanroom usage requirements will not be allowed inside the cleanroom. The Cleanroom supervisor has the last word.

- No cosmetics, tobacco products, handkerchiefs, tissues, food products, drinks, wooden/mechanical pen/pencils, perfumes, colognes, watches, jewellery, cassette players, phones, beepers, combs, cardboard or non-cleanroom approved papers are allowed.

- No blueprints, operation manuals or instruction sheets are allowed.

- Do not bring any tools/ equipment into the cleanroom from the maintenance shop to work in the cleanroom.

- No bare clothes are allowed inside the cleanroom.

- Do not expose any facial/head hair.

- Do not open the door to the cleanroom until the ON cycle of the air shower is over.

- Do not open the door to the cleanroom for communication or passing of products back and forth – use the pass-through instead.

- Do not use pass-through for storage.

- Do not block the air flow from the filter to the product.

- Do not congregate. No running and try to maintain silence.

7. What is Contamination?

Contamination is a process or act that causes materials or surfaces to be soiled with contaminating substances. There are two broad categories of surface contaminants: film type and particulates. These contaminants can produce a “killer defect” in a miniature circuit. Film contaminants of only 10 nm (nanometers) can drastically reduce coating adhesion on a wafer or chip. It is widely accepted that particles of 0.5 microns or larger are the target. However, some industries are now targeting smaller particles.

8. What specifications or standards apply to testing the filters in place?

Latest ISO 14644 replaces FED Std 209E.

9. With reference to Fed. Std. 209b, What is the relationship of the various classes of clean rooms ( 100, 10 000, and 100 000 ) to the 0.01% figure ?

There is no relationship at all. For example- a clean room with no one in it might be class 100, while the addition of personnel will send it into other higher categories. however, suppose the filters supplying a room were thoroughly checked for leaks, and all significant leaks were sealed, this room is operating at maximum efficiency with respect to the filters, and since the filters are mechanical in nature, there is nothing the operator can do to change conditions in this area.

The achievement of a particular class would relate to the number of air changes per hour as well as the scavenging design of the system.

10. Define Validation.

Validation is the process of establishing documentary evidence demonstrating that a procedure, process, or activity carried out in testing and then production maintains the desired level of compliance at all stages. In the pharmaceutical industry, it is very important that in addition to final testing and compliance of products, it is also assured that the process will consistently produce the expected results.

11. How is Air Changes per hour is calculated in Cleanrooms?

Air Changes per hour= Average airflow velocity* × room area × 60 min/hr.

12. How often should I validate my cleanroom to meet ISO 14644-1:2015?

It states the maximum time interval between airborne particle concentration testing of a cleanroom of ISO class 5 and below is six months and ISO class 6 and above is 12 months.

| Test Parameter | Class | Maximum Time Interval |

|---|---|---|

| Airborne particle concentrations | = ISO Class 5 | 6 months |

| Schedule of additional tests | >ISO Class 5 | 12 months |

| Airflow velocities in unidirectional airflow | All classes | 6 months |

| Airflow volume supply in non-unidirectional airflow | All classes | 12 months |

| Pressure differentials | All classes | Continuously monitored |

13. What are the clean room class limits according ISO Standard 14644-1?

Clean room maintained virtually free of contaminants, such as dust or bacteria, are used in laboratory work and in the production of precision parts for electronic or aerospace equipment. In the clean room standard ISO 14644-1 "Classification of Air Cleanliness" the classes are based on the formula:

Cn = 10N (0.1 / D)2.08 (1)

where Cn = maximum permitted number of particles per cubic meter equal to or greater than the specified particle size, rounded to whole number N = is the ISO class number, which must be a multiple of 0.1 and be 9 or less D = is the particle size in micrometers

| ISO Class | Maximum Number of Particles in Air (particles in each cubic meter equal to or greater than the specified size) | |||||

|---|---|---|---|---|---|---|

| Particle size | ||||||

| > 0.1 µm | > 0.2 µm | > 0.3 µm | > 0.5 µm | > 1 µm | > 5 µm | |

| ISO Class 1 | 10 | 2 | ||||

| ISO Class 2 | 100 | 24 | 10 | 4 | ||

| ISO Class 3 | 1000 | 237 | 102 | 35 | 8 | |

| ISO Class 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | |

| ISO Class 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 |

| ISO Class 6 | 1,000,000 | 237,000 | 102,000 | 35,200 | 8,320 | 293 |

| ISO Class 7 | 352,000 | 83,200 | 2,930 | |||

| ISO Class 8 | 3,520,000 | 832,000 | 29,300 | |||

| ISO Class 9 | 35,200,000 | 8,320,000 | 293,000 | |||

Contact Us

Air Calibre Systems

Address

Corporate Office

48/23, Vinayakar Koil Street,Krishnaswami Nagar,

Ramanathapuram,

Coimbatore 641 045.

Customer Support & Correspondence

21/11, Reddy Street,Virugambakkam,

Chennai 600 092.

Phone Number

044 4215 2074

Mobile Number

Customer Care: 9043022768

8807030868